The Future of Advertising: Spherical LED Display Innovations

/The advertising industry continues to evolve, fueled by the constant advancement of technology. From the simple print ads of the past to today’s digital billboards, businesses are always looking for new ways to capture and retain their audience’s attention. In this ever-changing environment, maintaining innovative display solutions is essential to stay ahead of the competition. The advent of spherical LED displays is a groundbreaking advancement that is revolutionizing the way businesses interact with their audiences.

As we delve into the future of advertising, it’s clear that spherical LED screens will play a significant role in changing the way businesses connect with their customers.

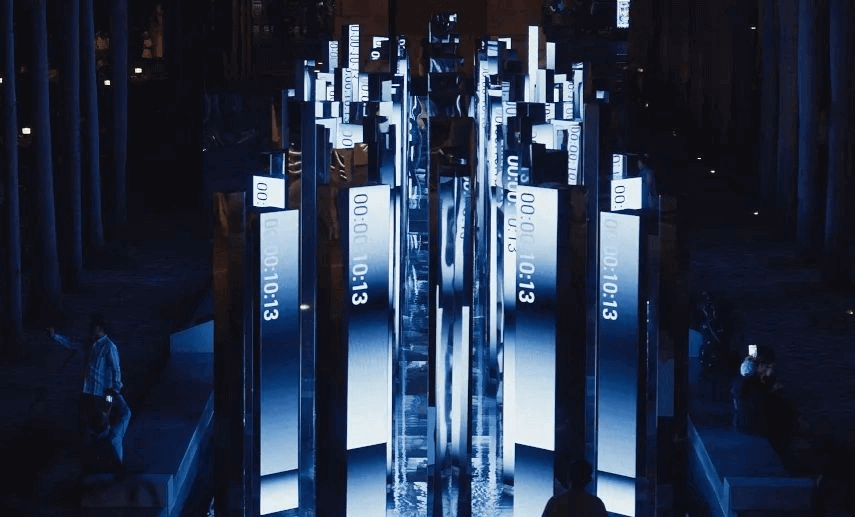

What is a Spherical LED Display Screen?

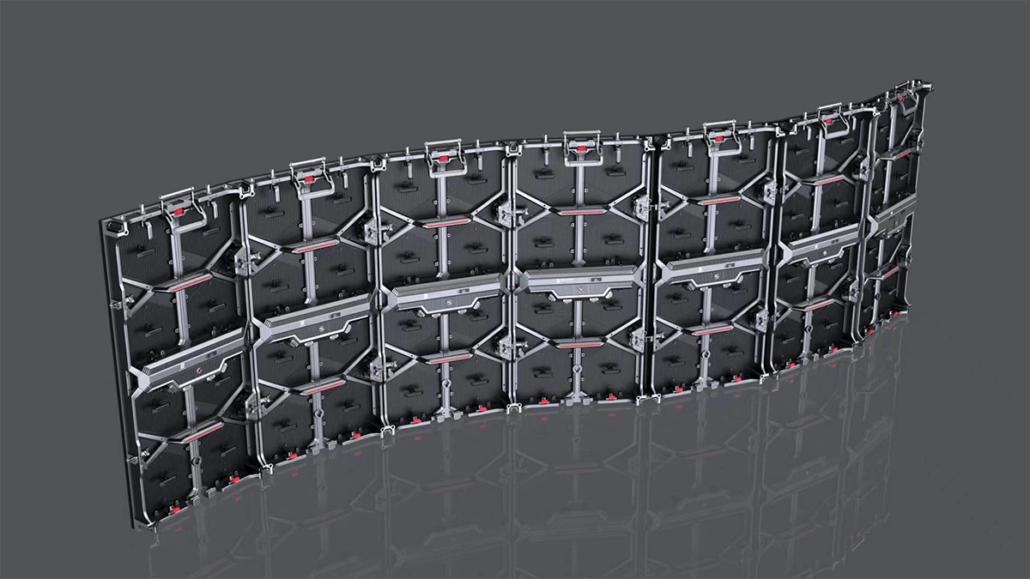

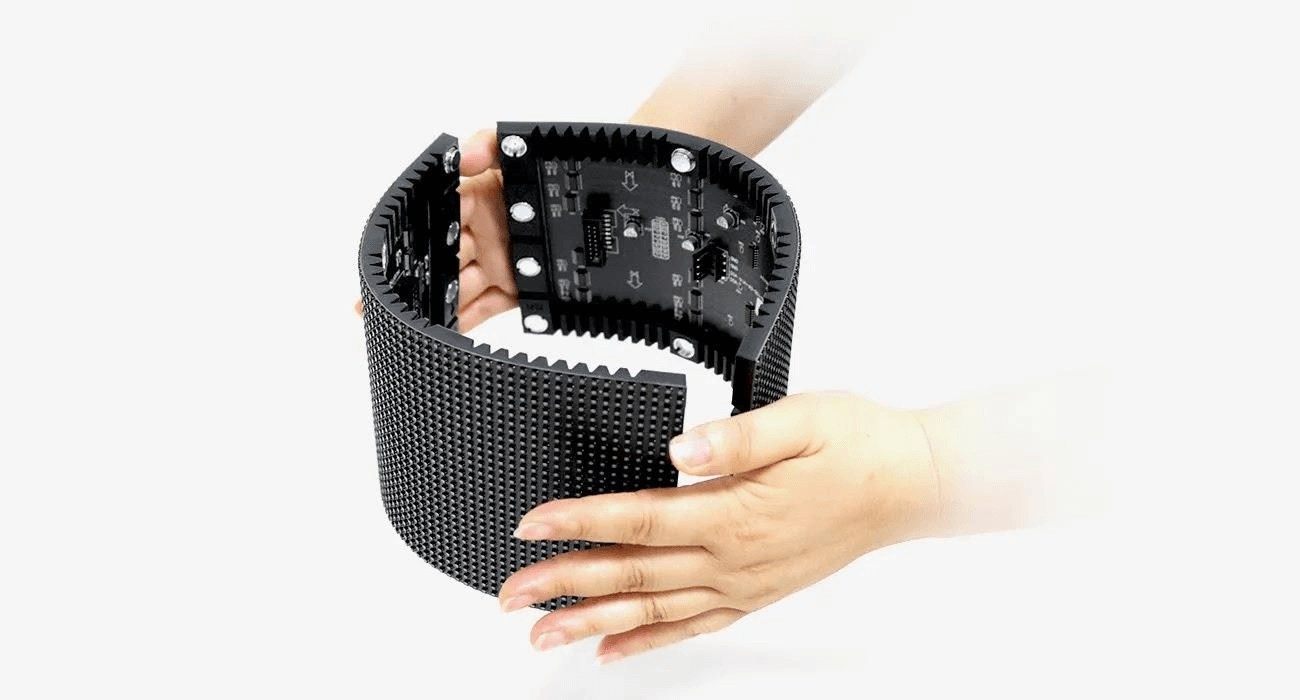

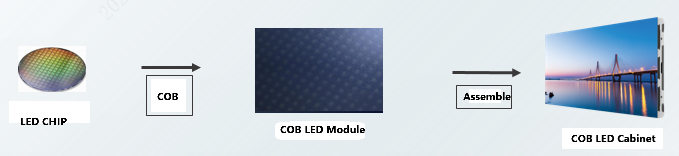

A spherical LED display is a cutting-edge digital display technology that breaks away from the traditional flat screen format and presents a three-dimensional spherical shape. It consists of multiple interconnected spherical units and a sturdy display board tray. The spherical units are made up of multiple scoops of display board assemblies ranging from indoor P2 to outdoor P37.5. They also contain multiple warp spokes and weft spokes that are interlocked through multiple tongue and groove joints to form a smooth curved surface.

This innovative display solution utilizes the versatility and brightness of LED technology to create a dynamic, immersive visual experience that can be viewed from any angle. The spherical design allows content to be displayed seamlessly across the entire surface, making it a powerful tool for capturing viewers’ attention in a variety of environments.

The Features of Spherical LED Display Screens

360-degree visibility for maximum impact

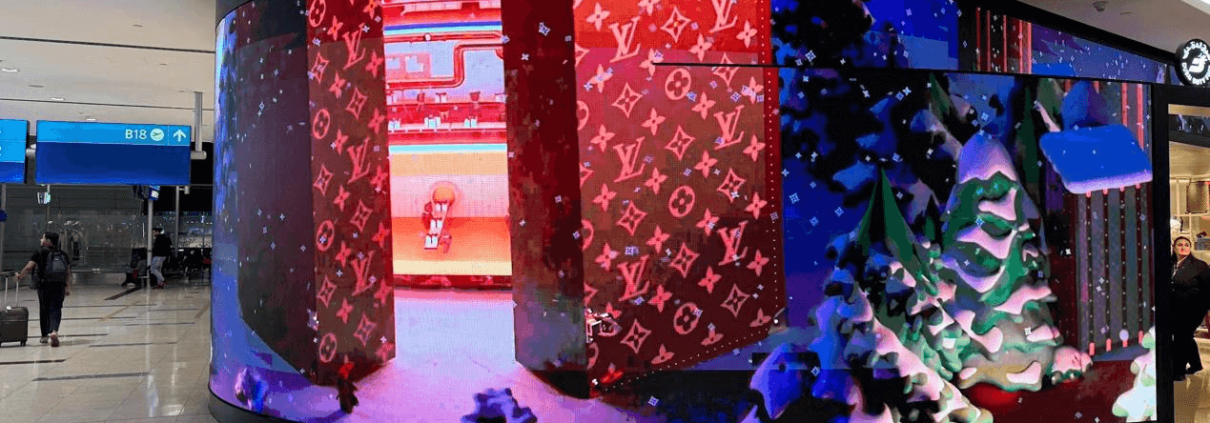

One of the most compelling features of a spherical LED display is its 360-degree visibility. Unlike traditional flat screens, spherical LED screens can be seen from any angle, ensuring that your message reaches a wider audience. This makes them ideal for environments where people are constantly on the move, such as busy commercial centers or large event venues.

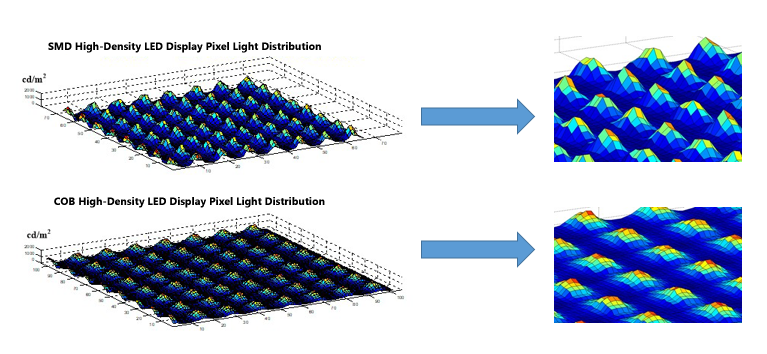

High resolution graphics and vibrant colors

Spherical LED displays use cutting-edge technology to deliver high-resolution graphics and vibrant colors. This ensures that every detail of your content is displayed with amazing clarity and brightness. Whether you’re displaying complex graphics, moving video or simple text, the quality of the display remains high.

Customization options for every business need

Every business has unique needs when it comes to advertising, and spherical LED displays offer a wide range of customization options to meet those needs. From different sizes and resolutions to different shapes and configurations, businesses can customize spherical LED screens to meet their specific needs. This level of customization ensures that the display fits perfectly with a brand’s identity and messaging strategy.

In addition, to ensure that the pixels are bright enough for outdoor reality projects, the front of the pixels are potted with silicone for waterproofing, and the color of the silicone can be matched to the project’s requirements against a color card, so that the spherical LED screen is perfectly coordinated with the color of the building’s façade.

Durability and weather resistance for indoor and outdoor use

Utilizing excellent silicone wires and specialized waterproof connectors, the fully sealed waterproof construction of the spherical LED displays is IP67 rated. Moreover, they can withstand indoor and outdoor temperatures of -20 and +80 degrees Celsius, and can operate in rainy weather.

Whether you install them in climate-controlled environments or outdoors where they are exposed to harsh weather, these displays can withstand harsh conditions while maintaining optimal performance. This durability ensures a longer lifespan and better return on investment for your business.

Interactive Dynamic Content Capabilities

Equipped with a professional audio and video processing system, the spherical LED display supports a wide range of external signal access for live broadcasting. In addition, multiple pixels can be connected in series or in parallel to achieve full-color display and clear video playback, and the LED ball can be synchronized or asynchronously controlled to display full-color video.

In addition, modern spherical LED displays do more than just show static images or looped video. They are interactive, allowing companies to engage with their audience in real time. For example, these screens can be integrated with social media platforms to display real-time information or programmed to react to audience interaction, creating a more engaging and personalized experience.

Energy efficiency and cost effectiveness

Despite their advanced capabilities, spherical LED displays are designed to be energy efficient. They consume less power than traditional lighting and display solutions, reducing operating costs. This energy efficiency, combined with their long lifespan and low maintenance requirements, makes spherical LED screens a cost-effective choice for businesses looking to maximize their advertising budgets.

Wide range of industry applications

Spherical LED screens are versatile and suitable for a variety of applications in different industries.

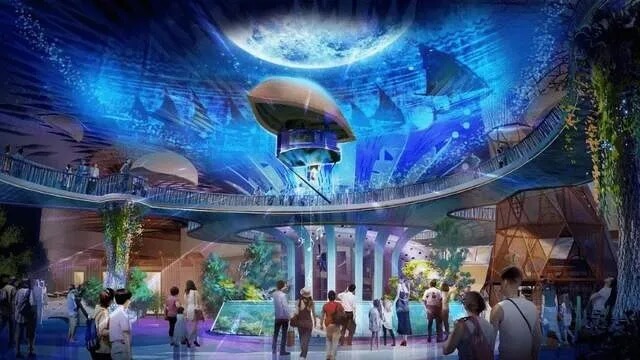

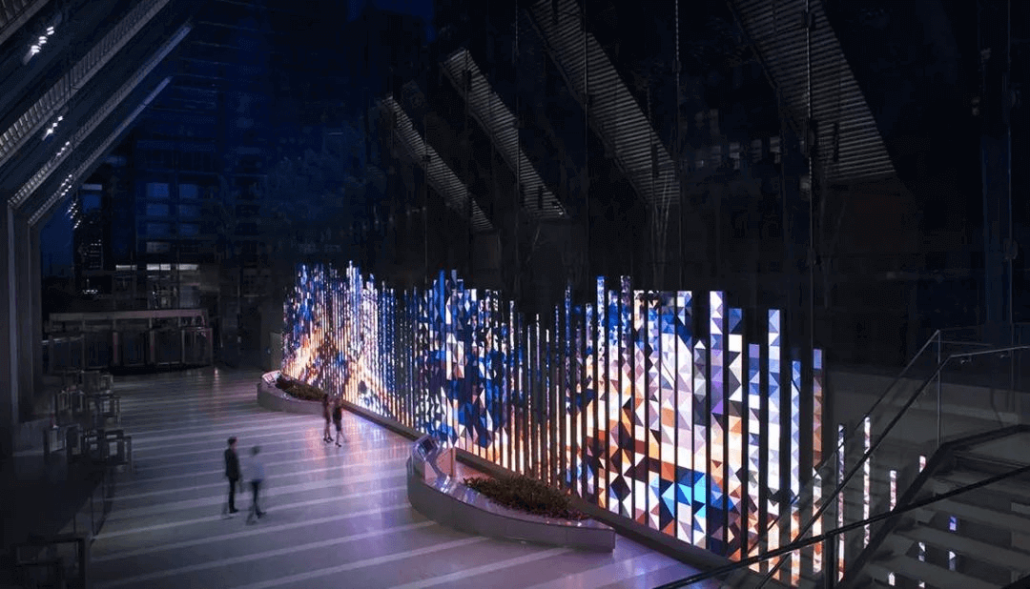

In retail environments, they can be used to create eye-catching product displays that engage customers and enhance the shopping experience.

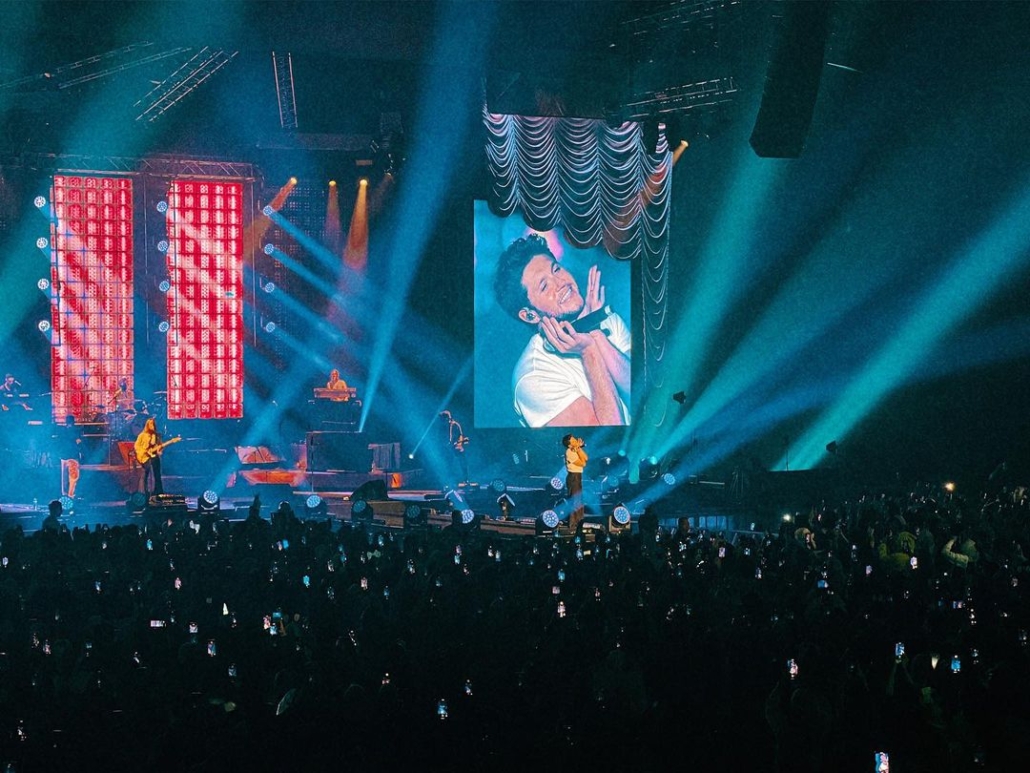

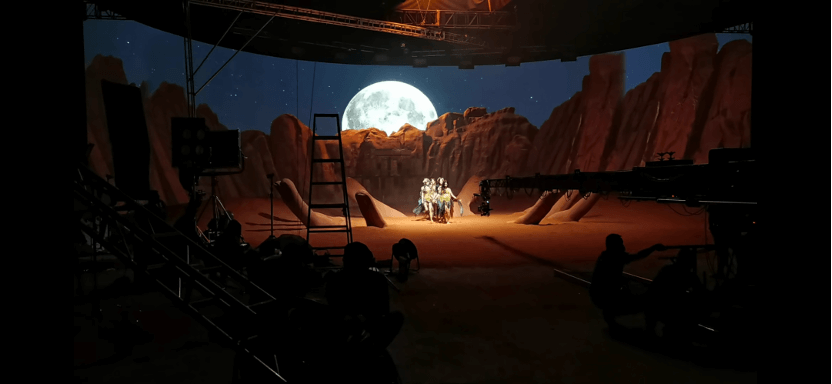

In entertainment venues such as concerts and theaters, spherical LED screens can enhance performances by providing dynamic backgrounds and immersive visual effects.

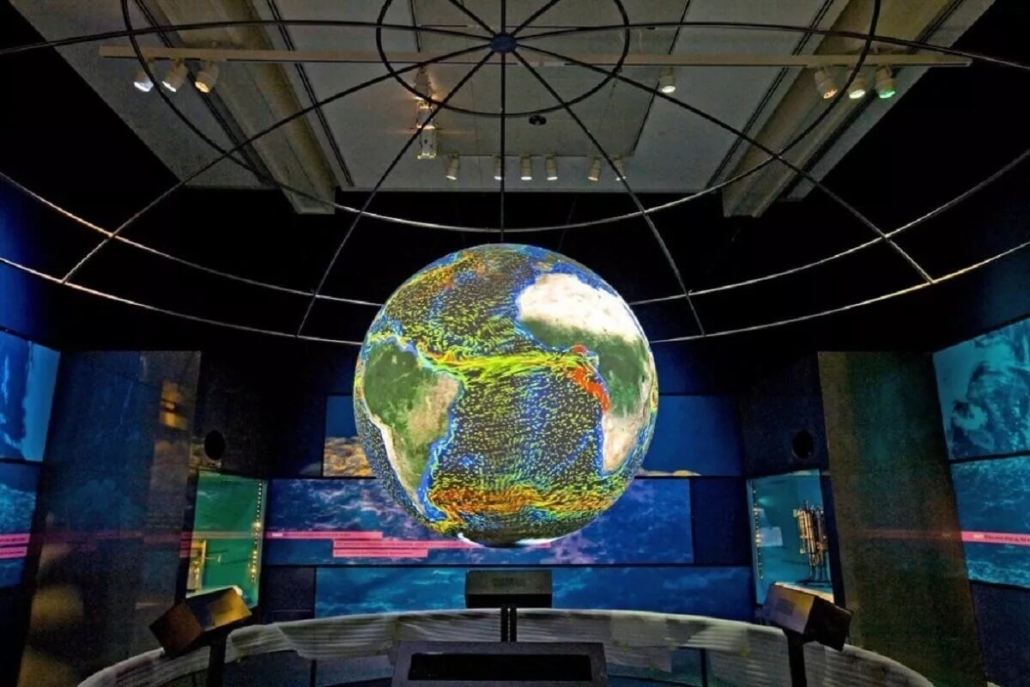

In addition, these displays are increasingly being used in government and corporate environments for presentations, trade shows, museums, planetariums and science museums, where their unique design helps create a memorable impression.

The Rise of Spherical LED Displays in Advertising

LED display technology has come a long way since its inception. Initially, LED displays were primarily used for simple signage and text displays due to their limited resolution and color capabilities. However, advances in technology have pushed LED displays to the forefront of modern advertising. As pixel density, color accuracy and overall brightness have increased, LED display screens have become the preferred choice for high-impact advertising.

While traditional flat panel LED displays have been the mainstay of advertising for many years, the introduction of spherical LED displays marks a significant change. The transition to spherical LED screens represents a shift to a more immersive and engaging advertising format.

Advantages over traditional displays

Spherical LED screens for advertisement offer several distinct advantages over traditional flat panel displays. Their 360-degree visibility ensures that the display can be seen from all angles, making them ideal for high-traffic areas where viewers approach from different directions. The spherical shape also allows for more creative and engaging content presentation, which enhances audience interaction and retention. In addition, the advanced LED technology used in these displays ensures excellent brightness, color accuracy and energy efficiency, making them a cost-effective solution for businesses looking to make a significant visual impact.

How to Enhance the Advertisement of Spherical LED Displays?

Super advertising value

LED spherical screen is a kind of creative LED spherical surface display, with multiple display splits, telescopic and shaped display, uniform technology display screen HD without distortion, super advertising value. Spherical LED displays have a stronger visual impact and their unique shape and design immediately attracts attention, making them ideal for high-traffic areas such as shopping centers, airports and trade shows. Spherical LED display breaks the limitation of traditional LED display’s regular shape and appears in different shapes, which brings another way of development in LED display industry.

Decoration and atmosphere

As a kind of novel display screen, LED spherical screen can play the role of modern decoration and atmosphere, and it has already been in the forefront of the advertisement tool that attracts thousands of eyeballs. With the gradual spread of the LED screen market, in the near future, both individual merchants and large brand manufacturers can take advantage of the LED screen to attract more customers, through the LED screen to introduce products and decorate the environment, so as to bring more economic benefits!

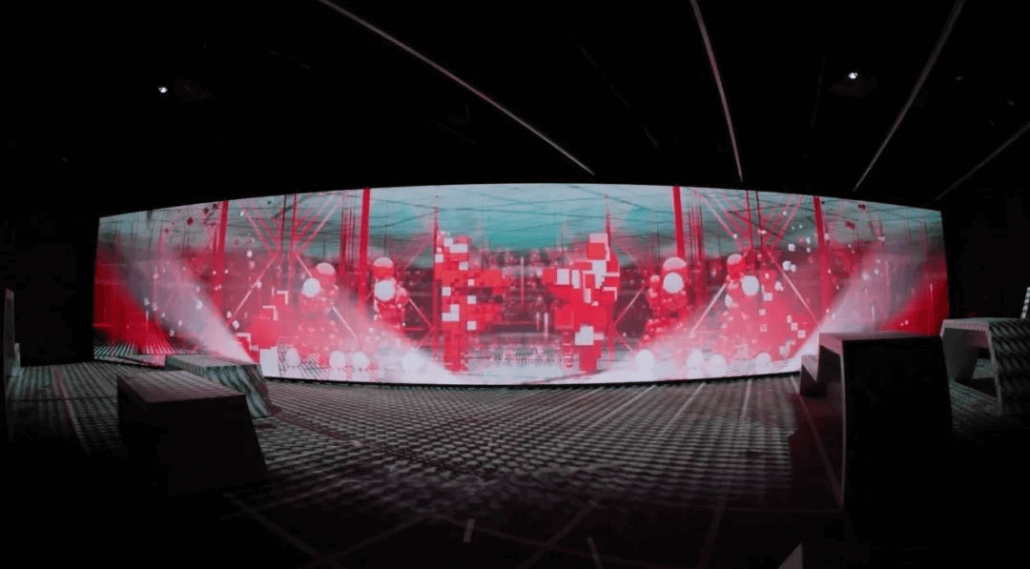

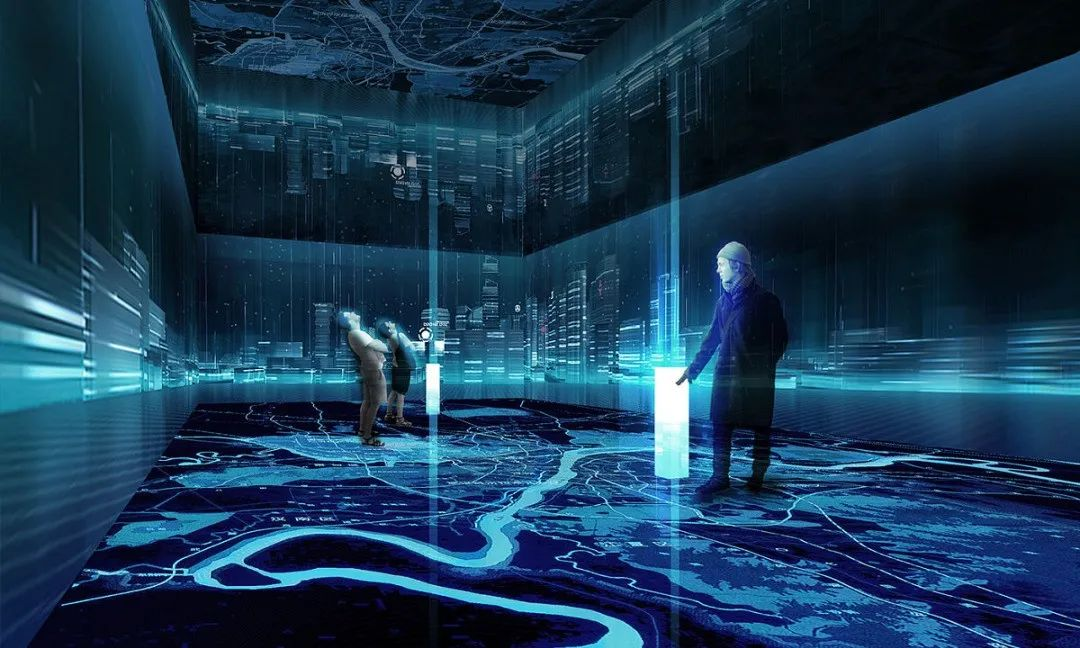

Immersive Visual Effects

Events are about creating memorable experiences, and spherical LED displays excel in this regard. Their unique design and high-quality visuals create an engaging and immersive effect that captivates attendees. Whether used for concerts, trade shows or corporate events, these displays enhance the overall atmosphere and leave a lasting impression on the audience.

Versatility to display dynamic content

One of the outstanding features of spherical LED displays is their versatility in displaying dynamic content. From live video feeds and animated graphics to real-time social media updates, these displays can handle a variety of content types. This flexibility allows event organizers to engage their audience with ever-changing and interactive visuals.

Choosing the Right Spherical LED Display for Your Business

Size

The size of your spherical LED display is one of the primary considerations. It needs to fit into your intended space while still being large enough to attract attention. For example, a smaller display may be suitable for indoor events or retail environments where viewing distances are relatively close. In contrast, larger displays are ideal for outdoor environments or large venues where the display needs to be viewed from a longer distance.

Resolution

Resolution is critical to the visual quality of a spherical LED screen. Higher resolution means more pixels per inch, resulting in sharper, more detailed images. For applications that require complex graphics or high-definition video, investing in a higher resolution display is critical. This ensures that your content is clear and stunning even when viewed up close.

Brightness

The brightness of your LED display is another important factor, especially for outdoor installations where sunlight can affect visibility. Higher brightness levels ensure that your content remains vivid and easy to read in all lighting conditions. For indoor setups, brightness can be lower, but still needs to be enough to stand out in ambient lighting.

Durability and weather resistance

Durability is key to a long-lasting investment, especially if the display will be used outdoors. Look for weatherproof spherical LED screens that are water, dust, and UV resistant. These features ensure that the display can withstand a variety of environmental conditions and provide reliable performance over time. Additionally, the durability and low maintenance requirements of spherical LED screens contribute to their overall cost-effectiveness.

Manufacturer reputation

Finally, consider the manufacturer’s reputation. Reputable manufacturers, such as RIGARD LED, are known for their superior build quality, cutting-edge technology, and excellent customer support. These factors make them a reliable and effective choice for businesses wishing to invest in a spherical LED screen, and RIGARD LED offers comprehensive support and service to ensure your spherical LED display runs smoothly. From professional installation and setup to ongoing maintenance and troubleshooting assistance, RIGARD LED is committed to providing its customers with first class service and support so that you get value for your investment.

Conclusion

The future of spherical LED display technology is bright, with several emerging technologies and innovations on the horizon. These include advances in micro-LED technology, which offers higher resolution and energy efficiency, and the integration of artificial intelligence to create more interactive and personalized advertising experiences.

Spherical LED displays represent the future of advertising, offering a unique and impactful way to engage audiences. Their innovative features, versatility and durability make them an excellent investment for companies looking to enhance their advertising strategies. RIGARD LED is at the forefront of the development of spherical LED displays, pushing the boundaries of what is possible.

By investing in research and development, RIGARD LED is able to provide cutting-edge solutions that meet the ever-changing needs of businesses. Our commitment to innovation ensures that our customers receive the most advanced and effective spherical LED display solutions.

Ready to change your advertising strategy? Contact RIGARD LED for expert advice and installation services. Let us help you engage your audience with the latest in spherical LED display technology.