COB LED Technology Powers LED Screens Toward Smaller Pixel Pitch

/LED display screens are undoubtedly the best solution for commercial displays today. A large number of LED beads are mounted in a dense arrangement on the panel to produce images by emitting light. And the distance between each tiny LED bead on the panel is called pixel pitch. As we all know, the smaller the pixel pitch of LED display screens, the higher the resolution and the higher the picture quality presented.

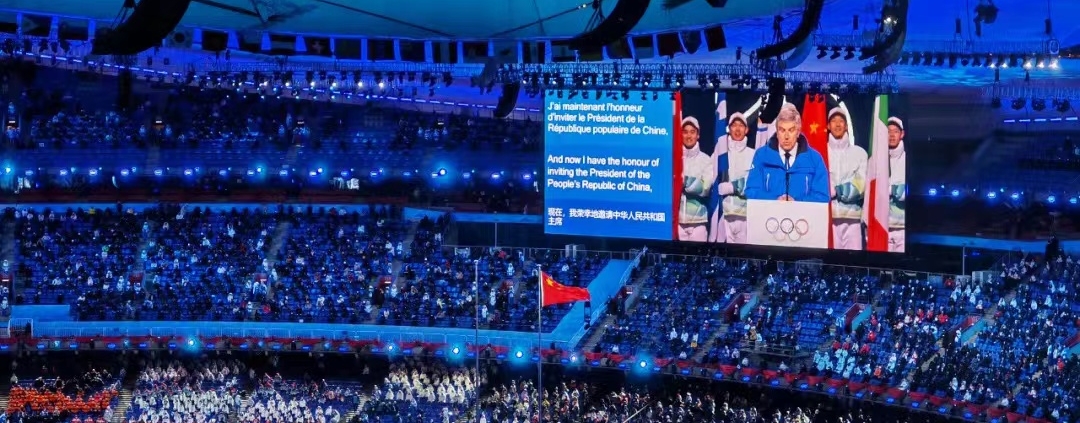

The demand for ultra-high definition displays (UHD) rises in recent years due to the rich image detail and immersive viewing experience they provide, especially when viewed at close range. For enterprises, UHD displays exert great influence in the clear and distinctive presentation of the corporate image and product details, which plays a positive role in business development. There is no doubt why Micro LED and Mini LED, the display terminals that provide UHD images, are the wind vane of future display technology.

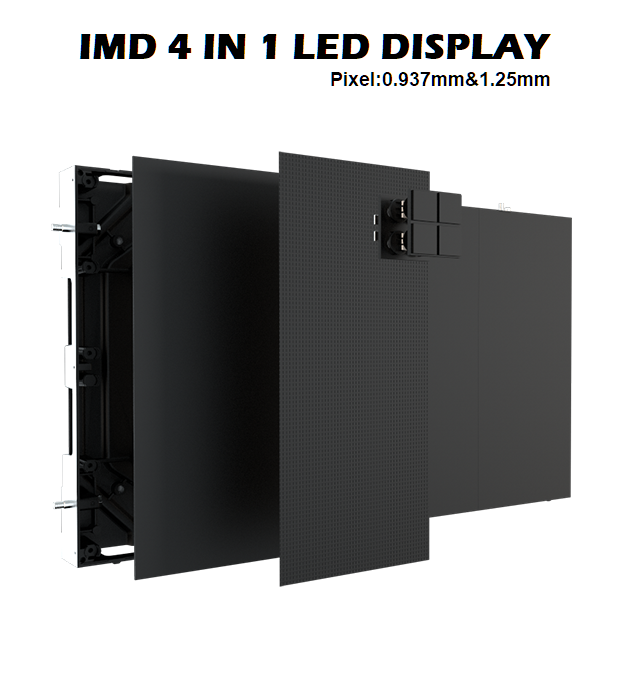

Small pitch LED displays are starting to surpass the maximum resolution of UHD panels in the LED display industry. LED display screens with pixel pitches below 1 mm are gradually making their way from the high-end market to the mid-to-high-end market thanks to ongoing advancements in LED packaging technology, significant improvements in packaging efficiency, and a development trend of rapidly decreasing LED chip cost.

At the annual conference for Integrated Systems Europe (ISE) 2023, the P0.3 LED display screen made its debut. Due to the extremely small pixel pitch, the P0.3 LED display can reach a resolution of 6,547,622 dots per square meter and still have a high brightness of 1200 nits.

The debut of the P0.3 LED display screen demonstrates both the advancement of fine-pitch LED display technology and the inevitable trend toward Mini LED or Micro LED as carriers for ultra-high definition displays.

The COB LED packaging technology, which has steered the LED display industry in the direction of ultra-high resolution displays and is a crucial element in obtaining decreasing pixel pitches in LED displays, is credited as one of the reasons for the successful debut of P0.3 LED screens.

So, what is COB LED, and how can COB LED technology reduce the pixel pitch in LED displays?

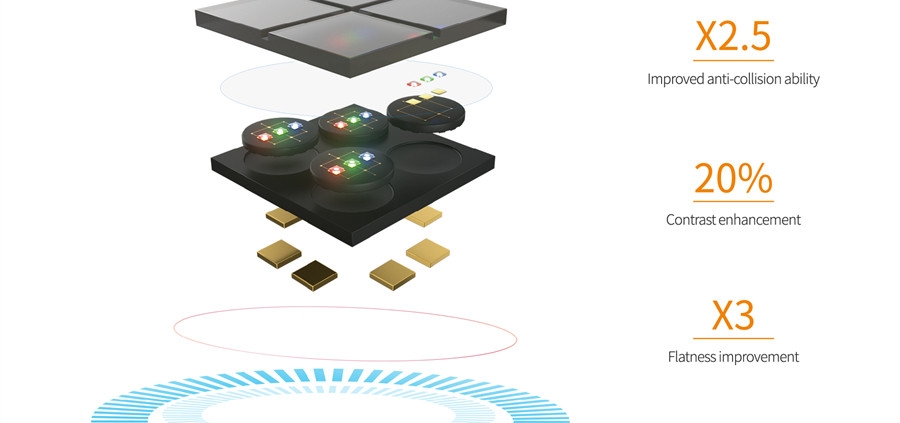

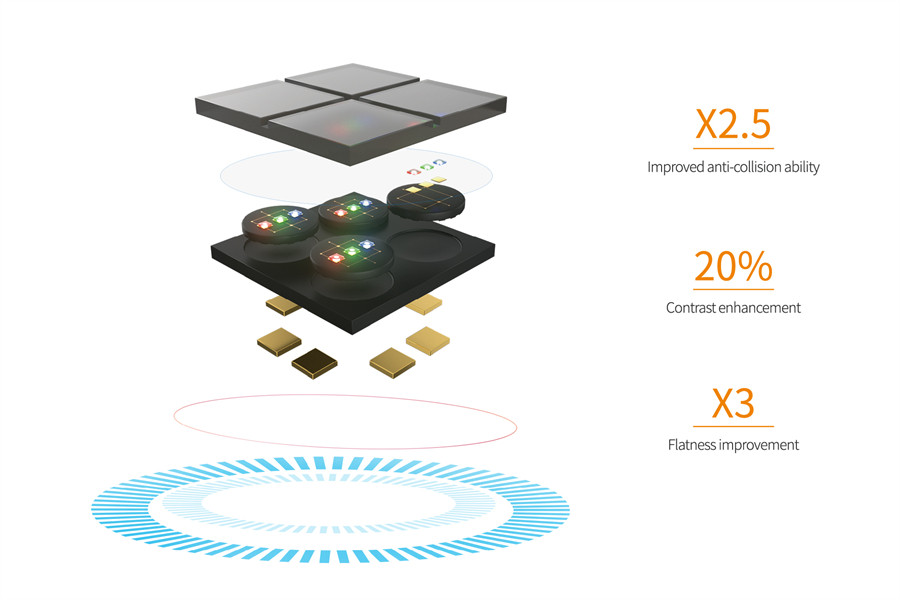

COB (chip-on-board), is a new LED packaging technology that mounts LED chips rather than LED beads directly on the Printed circuit board (PCB).

- High-density array of LED chips

Because each LED chip is exposed, i.e., there are no lead frames, phosphor coatings, or lenses, they can be arranged and mounted very closely on a single COB LED module. Such a high-density array allows COB LEDs to produce more light output and greater light uniformity from the same area that a standard LED module might occupy.

For example, COB LED technology can produce 38 times more LEDs on a 10mm x 10mm square PCB compared to DIP LED technology, and 8.5 times more LEDs compared to SMD LED technology. With COB LED technology, P1.2mm, P0.9mm, P0.6mm, P0.5mm, and even P0.3mm LED display screens can be achieved.

- Fewer components

The reduction in the number of parts required to operate the LED chips is another significant benefit of employing COB LED technology. Instead of the lens and other standard components of an LED package, COB LEDs power the multiple diode chips they house using a single circuit with only two connections. Each LED chip in this case produces less heat and has a lower failure rate thanks to the fewer components and removal of the conventional LED chip structure packaging.

- Lower failure rate

The ability to limit the pixel failure rate to 1-9 pixels within 1 million display pixels is another feature of COB LED technology’s low failure rate. The current standard SMD LED technology in the display industry can only control the pixel failure ratio to one in 10,000, which is far from being able to meet the requirements of small-pitch LED display screens for ultra-high definition display.

We are all aware of the benefits of COB LED displays, including their extremely high contrast ratio, increased brightness, and wider color spectrum. Long-term improvements in COB LED display efficiency, current density, and lamp bead stability are possible thanks to the prospect of smaller pixel pitches, a more straightforward packaging technique, and good heat dissipation performance. This will encourage the ongoing development of Micro LED display screens.

In addition to assisting the display industry in its transition to the UHD age of p0.Xmm, COB LED technology also creates a new environment for creative, forward-thinking uses of LED display screens. Future XR and meta-universe applications will be continuously and thoroughly integrated with COB LED display technology. It keeps tightening up its specifications for the unit display area resolution level and other information-carrying capacity indications. Future high-end display applications for COB LED technology will be built on the cutting edge of ultra-micro pitch technology.

The secret to unlocking the enormous potential for future UHD display development is the specialized market for narrow-pitch display technology. You can consult for RIGARD narrow pixel pitch LEDs if you are looking for Mini LED screens or even Micro LED screens. We have a sizable market share in many different kinds of small-pitch LED displays thanks to our mastery of COB technology. Moreover, RIGARD fine pitch LED displays can offer you excellent image quality, and consistent and accurate color performance with refresh rates up to 3840 Hz, and brightness levels of 4000 nits.

Want to learn more about COB LED technology and small-pitch LED display screens? RIGARD will be pleased to assist you if you contact us right away!