What is GOB LED Display Technology?

/LED packaging technology is constantly being improved in response to the increasing demand for small pitch LED screens, such as Mini LED and Micro LED, that can deliver ultra-high quality image display.

Due to its inherent deficiencies in protection and point source display performance, the initial SMD technology is no longer able to fulfill the application of all scenarios. COB technology, as a newcomer, has not yet achieved mass production due to high technical costs, poor color separation, and the inability to mix lights. In this context, the GOB LED display technology, which has been improved from the SMD packaging process, has come into being.

SMD vs COB vs GOB LED Technology

● What is SMD LED Display?

Surface Mount Device, often known as SMD, is the packaging of lamp cups, brackets, chips, leads, epoxy resin and other materials into different sizes of LED beads, which are then directly soldered on printed circuit boards (PCBs).

Due to the lack of protection on the surface of SMD-packaged LED screens, the lamp beads are exposed to the outside environment, which raises the danger of color shift, the failure and damage of LED beads.

● What is COB LED Display?

By encapsulating the LED chip directly on the PCB rather than the LED lamp, Chip on Board (COB) is an advancement of SMD technology that lowers the potential risks that SMD LED displays may have. However, because of the high technical cost and the challenge of maintaining color uniformity and chromatic aberration, COB LED screens are currently difficult to mass produce.

● What is GOB LED Display?

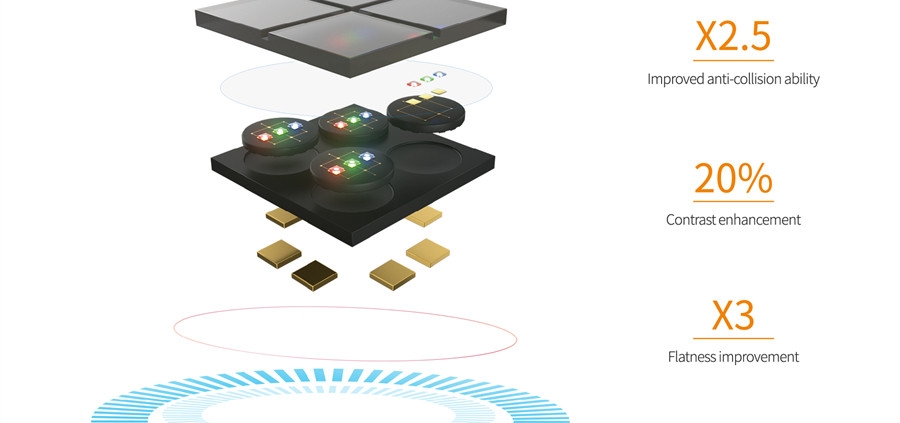

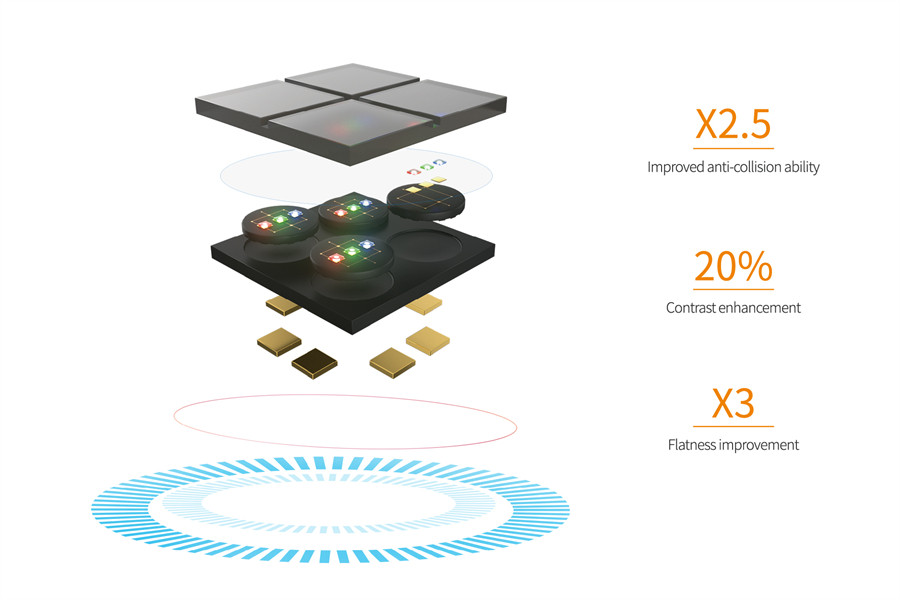

Glue on Board (GOB) is a new revolutionary packaging method that outperforms SMD technology by using glue on the PCB to encapsulate the LED modules. Essentially, GOB LED display technology is an analog of module packaging. It uses a proprietary transparent epoxy adhesive applied to the surface of PCB modules that have been soldered with thousands of SMD lamps to form a special shield. GOB display technology provides a solution to the LED beads protection.

The highest benefit of GOB LED displays over SMD is the high level of protection for the LED beads, which enables LED screens to adapt to any challenging environment and attain true moisture-proof, water-proof, dust-proof, impact-proof, and UV-proof properties. In contrast to the high-cost COB technology, GOB LED display not only achieves mass production at a lower cost but also successfully addresses issues like poor surface flatness, poor color separation and inability to mix lights of COB.

Advantages of GOB LED Display

-

Superior Durability – waterproof, moisture resistant, dustproof, shockproof, UV resistant

Splashing water, moisture, or dust can easily enter and gather in the gaps of the LED module if the surface is left untreated and exposed to the outside environment. In addition to lowering the quality of the image display and making it more difficult to clean the LED display, this will also make the LED chips or beads more prone to damage. What’s worse, the LED chip is susceptible to accidental collision damage while being handled, which will result in display malfunction across the LED display screen.

The transparent epoxy adhesive on the surface of the GOB LED displays can effectively shield the LED chips or beads from any harsh external elements like water, moisture, dust, and UV radiation. Moreover, the high density of the glue makes the GOB display screen shockproof, greatly reducing the risk of potential breakage due to collision during installation and delivery.

-

Excellent thermal conductivity extends service life

In addition to superior transparency, GOB LED display screens also have excellent thermal conductivity, which means that the heat generated by the LED units drains more quickly, significantly prolonging the life of the LED display.

-

Cost-effective

GOB LED displays are more reliable and durable than traditional LED display screens, which results in a longer lifespan and lower maintenance costs. As GOB LED display screens don’t require as much maintenance and replacement as traditional LED displays, they are more economical.

-

Maintain superior image quality

The brightness, color, or clarity of the image displayed by the GOB LED display screen is not diminished, even better than the conventional ones, as a result of the superior transparency of the glue on board.

-

Easy to install

GOB LED displays are easier to handle and quicker to install since they are coated by a clear epoxy adhesive, which makes them less brittle.

-

Easier to clean

Because of the clear epoxy covering the surface for smoothness, the cleaning of GOB LED display screens is quick and simple with a soft cloth and light cleaning agents. Furthermore, GOB technology shields the LED units from harsh cleaning products.

-

Wide range of applications

The flexibility and versatility of GOB LED display solutions is unparalleled. Since GOB LED display technology combines the advantages of traditional SMD and COB, while compensating for their shortcomings. GOB LED displays can be used in a variety of scenarios, such as small pitch LED screens, rental LED screens, etc., driving revolutionary changes in the entire LED display industry.

Application of GOB LED Display

-

Fine Pitch LED Display Screens

The continuous development of the narrow pixel pitch LED display market has taken GOB technology to the next level. Each LED bead or chip in fine pitch LED display screens is spaced closer together and more densely throughout the PCB. The display industry of today has made it possible to produce LED screens with pixel pitches less than 1mm and pixel pitches between P1.2 and P2.5 are already in mass production.

The tiny LED beads and LED chips are easily damaged during shipment, installation, and operation with such a small pixel pitch. GOB LED display technology is the perfect solution to this problem, as the glue on the board protects the LED beads or ships well, which can be used for smaller pixel pitch LED display screens.

With the aid of cutting-edge GOB LED display technology, RIGARD, a specialist in fine pitch LED display solutions, has been able to produce and manufacture LED display screens with smaller pixel pitches, such as P1.2 LED displays. In fact, we provide P1.2, P1.5, P1.8, and P2.5 LED displays for indoor and outdoor UHD applications, depending on the various needs of our users, which are intended to give your audience a dazzling visual feast and significantly advance your business.

-

Rental LED Screens

The rental LED screens that are set up on the stage require regular installation, disassembly, packaging, and movement, as we are all aware. In this case, it is challenging to prevent damage to the LED lights from unintentional impacts, even with the highest quality and most expensive LED display screens. It also raises maintenance costs because they need frequent repairs if damaged. However, with GOB LED display technology, Rental LED display screens can be well-protected and maintenance expenses can be reduced.

RIGARD is a reputable name in rental LED screens as well as a full-service provider of LED display solutions. With GOB display technology, our P1.5, P2.6, and P2.9 LED displays have successfully delivered flawless image displays for thousands of stage displays around the world, resulting in effective cost savings and business growth.

-

Transparent LED Screens

In commercial settings like retail stores, malls, and nightclubs, transparent LED display screens are becoming more and more common. Transparent displays utilize extremely small PCBs in order to achieve high transparency while keeping high resolution, making the lamps and PCBs exceedingly brittle and susceptible to damage. GOB display technology provides protection for the entire hollow module of transparent LED screens, lowering the chance that the screen would be damaged in a collision.

-

Flexible LED Screens

Today, a variety of curved and cylindrical LED video walls are produced using flexible LED screens. GOB LED display technology can boost the reliability of flexible LED display screens by shielding them from moisture damage and scratches, even if the installation is often fixed.

-

Floor LED Screens

Typically, there is a layer of acrylic cover on the surface of floor LED screens for interactivity to prevent stepping on. However, the acrylic cover has poor light transmission, which has an impact on the visual effect. The floor LED display can be best protected from being trodden on by GOB display technology, which not only offers greater light transmission and visual effect but also has waterproof, shockproof, and dustproof features.

On the other hand, there are gaps between the LED beads, the traditional floor LED for interactivity will show grainy pixel dots, which negatively affects the interactive experience. By changing the display screen from a point light source to a surface light source, GOB LED display screen may produce a more uniform luminescence, UHD display, and wider viewing angle.

-

Irregularly shaped LED Screens

An irregular shape of the LED display screen is typically needed to build a special ambiance in clubs, pubs, casinos, and other locations. These locations are packed though, so collisions, spilling food or drinks on the display screens are bound to happen, all of which could harm the LED display screen. Due to its shock, water, and moisture-resistant properties, GOB LED display technology shields irregularly shaped LED displays from potential harm brought on by pressure, water, food, etc.

As an innovative LED packaging technology, GOB LED display breaks the barrier of traditional SMD LED display and adds more vitality to the LED display market by virtue of lower cost than COB LED display towards smaller pitch display.

If you are looking for small pitch LED displays encapsulated by GOB technology, do not hesitate to contact RIGARD. As an expert in LED screen technology and integrated LED solutions, RIGARD keeps up with the industry trend and masters the most cutting-edge GOB LED display technology to break through the technical barriers of fine pitch LED display screens in order to help your business development.