COB LED vs. SMD LED, What is the Difference?

/Ultra-high definition (UHD) monitors, along with advancements in LED packaging technology and improved packaging efficiency, have gradually become the trend in LED display screen development. It’s widely known that the smaller the pixel pitch of an LED display screen, the higher the resolution and the better the picture quality. In recent years, COB (Chip on Board) and SMD (Surface Mount Device) technologies have been dominating the small-pitch display market, serving as key elements in achieving a smaller pitch for LED display screens.

While both COB LED and SMD LED technologies have their unique characteristics and advantages, we often hear claims that COB, with its various technological advantages, surpasses traditional SMD. In this article, we will explore COB LED vs SMD LED technologies to help you make a wise decision when choosing the LED display screen that best suits your specific needs.

What is SMD LED Technology?

SMD stands for Surface Mount Device, which is a type of LED packaging technology that directly mounts LED chips onto a printed circuit board (PCB) using surface mount technology. In other words, materials such as lamp cups, brackets, and crystal components are packaged into different specifications of light beads, which are then soldered onto the circuit board through high-speed SMT machines using high-temperature reflow soldering.

SMD LEDs are known for their energy efficiency, and ability to produce perfect color. They enable more compact and versatile designs, making them suitable for various applications with limited space, such as electronic devices, lighting fixtures, automotive lighting, displays, and signage.

What is COB LED Technology?

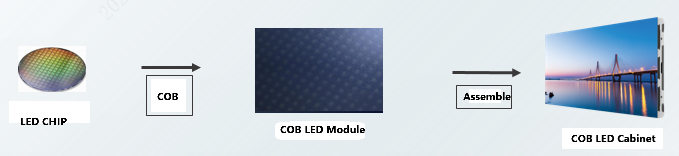

COB stands for Chip on Board, and it’s a new LED packaging technology that is ahead of SMD. COB LED technology involves mounting multiple LED chips directly onto a ceramic or metal substrate, and then encapsulating them to form a single unit module, which is then assembled into a complete LED screen. The LED chips are closely packed in an array, resulting in higher levels of light output and better heat management.

COB LED is known for its high light output, excellent heat management, and uniform light distribution. Its closely arranged LED chip array also allows for better color mixing. Therefore, COB LED technology is very suitable for indoor and outdoor lighting, commercial displays, and horticultural lighting where high levels of brightness and performance are crucial.

Differences Between COB LED and SMD LED

-

Light Quality

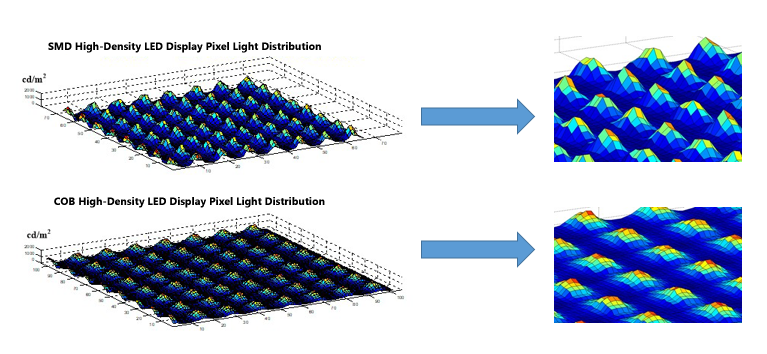

In a COB LED display, the closely arranged array of LED chips allows for better color mixing and uniform light distribution. SMD LED displays have individual light beads, resulting in a point light source effect. In contrast, COB LED displays have an overall encapsulation above the light-emitting chips, which transforms the light source into a surface light source after scattering and refraction through the encapsulation.

Point light sources can cause glare because the light produced by SMD LED technology is the result of many light sources coupling together. In contrast, surface light sources have a more uniform overall light, providing better visual perception and reducing eye strain, making them more suitable for prolonged close-range viewing.

-

Contrast

After overall encapsulation using new processes, COB LED displays can achieve a contrast ratio of over 20000:1, whereas SMD LED displays typically do not exceed 10000:1. As a result, when viewed from the front, COB LED screens offer a viewing experience closer to that of LCD screens, with vivid colors and better detail representation.

-

Brightness

The difference in brightness between COB LED technology and SMD LED technology is due to variations in lumens. For COB LED display screens, there are at least 80 lumens per watt, while for SMD LED displays, it ranges from 50 to 100 lumens per watt. Therefore, COB LED displays have higher brightness, resulting in better image quality.

-

Color and Color Temperature

In terms of color and color temperature, SMD LED technology surpasses COB LED technology. SMD LED technology uses the three primary colors to provide a wider color range and has stronger color temperature adjustability. On the other hand, COB LED displays cannot individually select and match the optical performance of each light bead-like SMD screen. Instead, they only allow for emitting a single color, which can lead to color inconsistency when viewed from wide angles. However, precisely because COB LED emits only one color, it can provide more stable lighting.

-

Reliability

Since the light-emitting chips of SMD LED displays are packaged before being mounted, they have weaker overall protection and are more susceptible to damage from collisions. Additionally, SMD screens have poor water, moisture, and dust resistance, and cannot be wiped clean. However, they are convenient for on-site repairs and beneficial for later maintenance.

COB LED display screens use high-standard coating technology, with a front protection level of up to IP65, protecting against collisions, scratches, as well as damage from water, moisture, and UV rays to the internal components.

Additionally, due to the fewer number of components and the elimination of traditional LED chip structure packaging, COB LED generates less heat from each LED chip. Excellent heat management enables COB LED displays to support all-weather operation, even in extreme temperatures ranging from 30 to 80 degrees Celsius.

However, due to the overall encapsulation of COB LED screens, on-site repairs are not possible, requiring professional equipment and factory servicing, which can be inconvenient.

-

Energy Efficiency

Compared to SMD LED display screens, COB screens have higher energy-saving benefits. This is because the light-emitting diodes (LEDs) inside SMD LED displays often use a positive mounting process, leading to wire obstruction above the light source. In contrast, COB LED displays mostly use an inverted mounting process, resulting in unobstructed light sources. Therefore, at the same level of brightness, COB LED screens have lower power consumption and are more cost-effective.

Additionally, the epoxy resin used to encapsulate SMD LED displays has lower transparency, while the overall encapsulation used in COB LED displays has higher transparency, further enhancing the cost-effectiveness of COB LED displays.

In summary, when comparing COB LED and SMD LED technologies, COB LED has unparalleled advantages in terms of light quality, contrast, brightness, reliability, and energy efficiency, while SMD LED technology excels in color and color temperature adjustability. By understanding the differences between these two technologies, you can make informed decisions and choose the LED packaging technology that best suits your specific needs.

RIGARD is a leading manufacturer of LED display screens in the industry. With expertise in both SMD LED and COB LED technologies, we have a significant market share in various fine pitch LED display fields. RIGARD small pitch LED displays offer outstanding image quality, consistent and accurate color performance, brightness levels of up to 4000 nits, and highly cost-effective energy efficiency. Whether you are seeking high brightness and reliability or compact size and excellent color, we can tailor a suitable COB LED or SMD LED solution for you.